How to be producer of line for potatoes and onions sorting

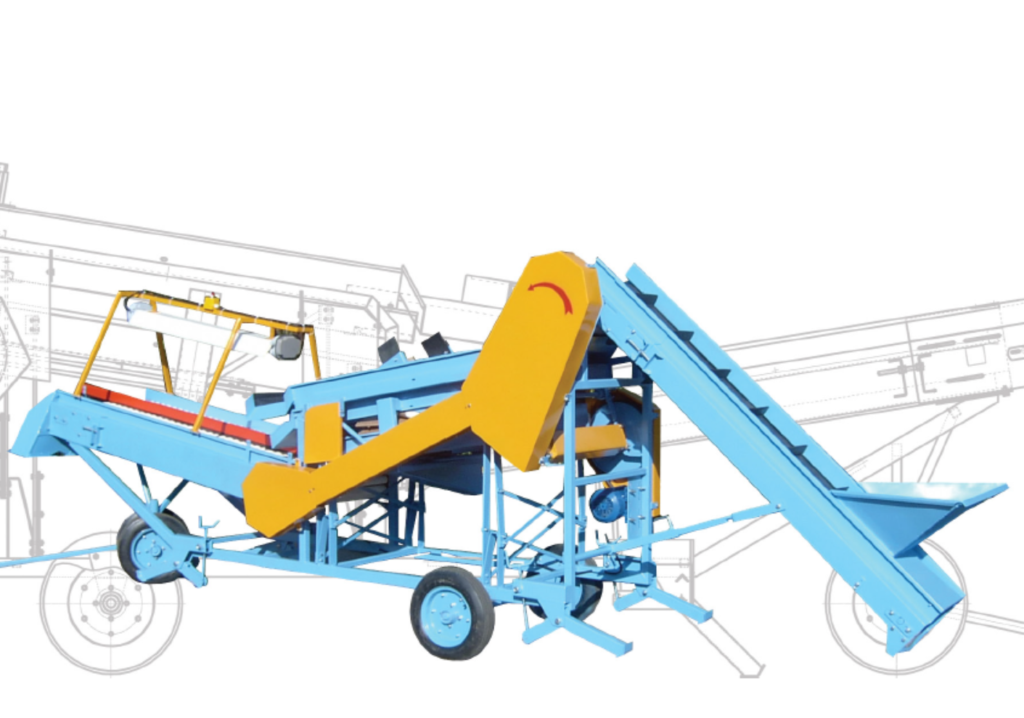

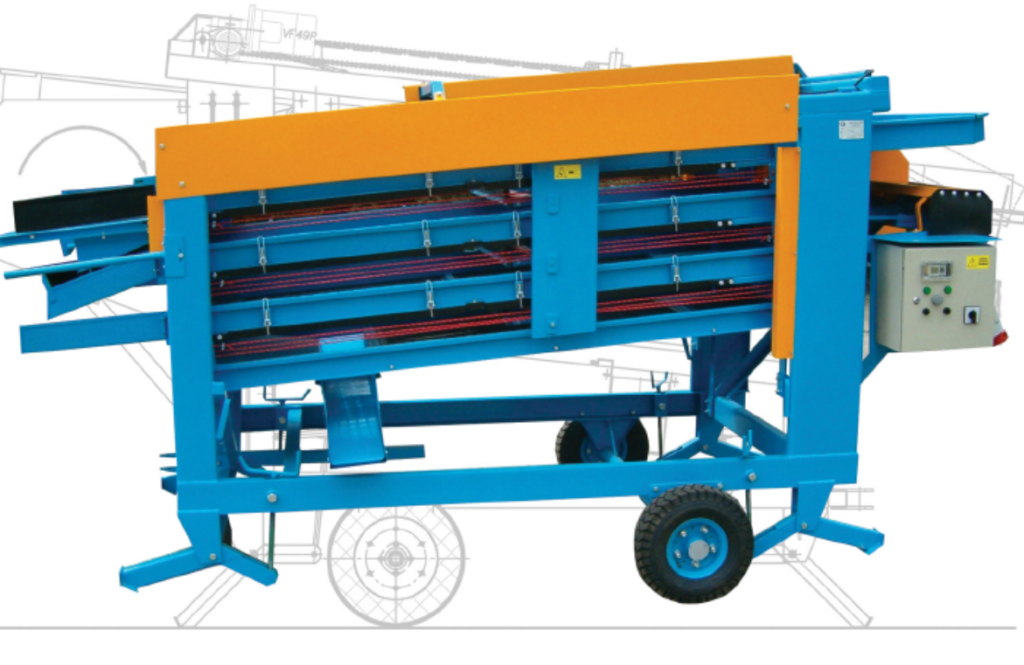

Line for sorting potatoes, onions into four dimensional fractions.

This line is intended for sorting potatoes, onions into four dimensional fractions.

The set consists of a feeding conveyor, sorter and

roller selection table – the whole drive is a three-phase motor.

The sorter is equipped with three exchangeable screens with external dimensions 112 x 60 cm and square meshes with dimensions according to the customer’s choice from 25 x 25 mm to 90 x 90 mm in the range

every 1 mm and in one solid sieve grate to receive the so-called sieve fraction, i.e. the smallest raw material.

The selection table has 50 mm rotary rollers on which manual selection and elimination of the damaged one takes place raw materials. The table is equipped with lighting and the end is a bag for four bags. M 612 set

has four 400 mm wheels and a transport drawbar as well as fixed bolted supports for stationary work.

The set is also produced in a separate version, consisting of a feeding conveyor, sorter andselection table, which have their own independent drives.

Technical characteristics:

- length: 6.5 m

- width: 1.5 m

- height: 1.9 m

- weight: 600 kg

- efficiency: up to 5t / h

- engine power: 0.55 kW

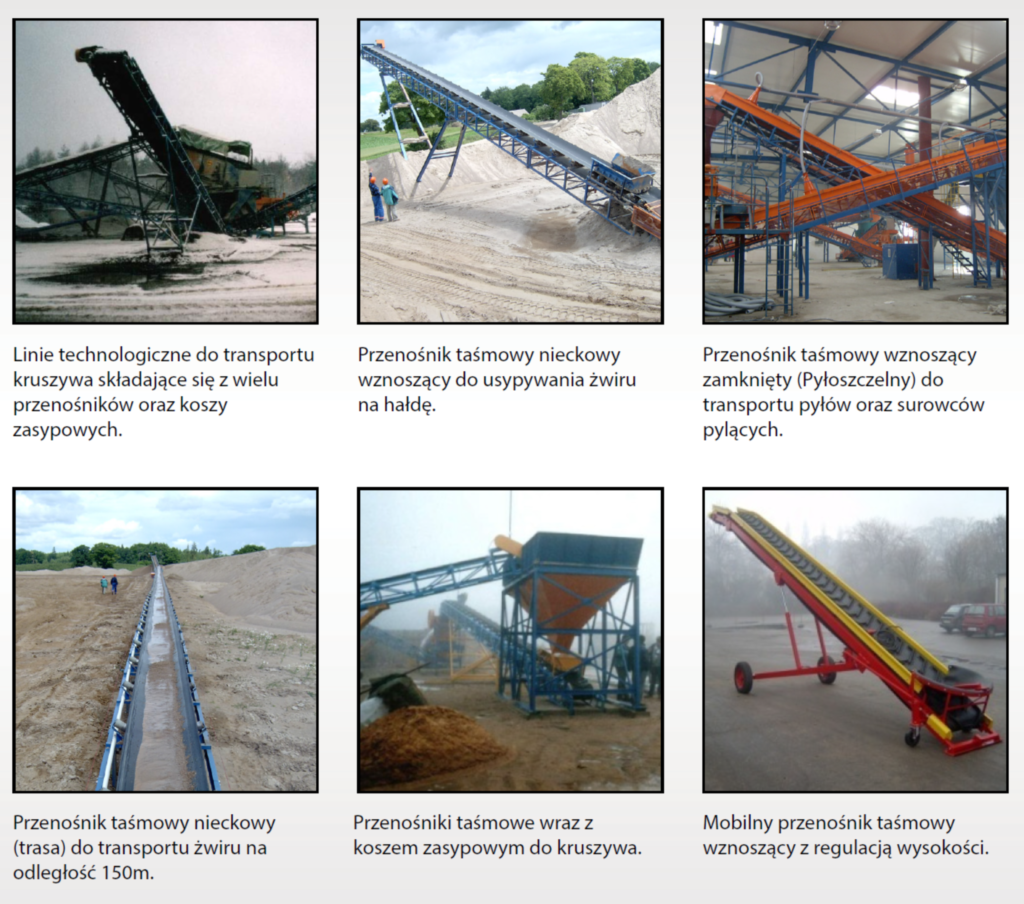

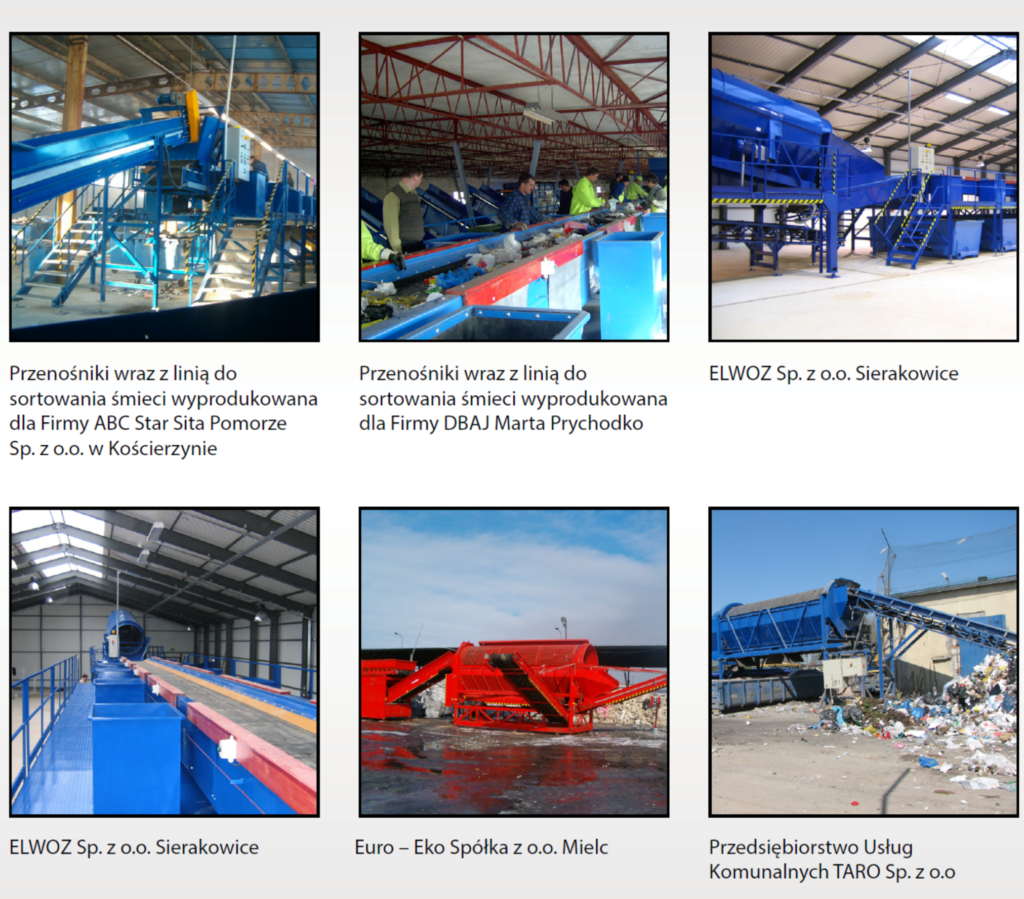

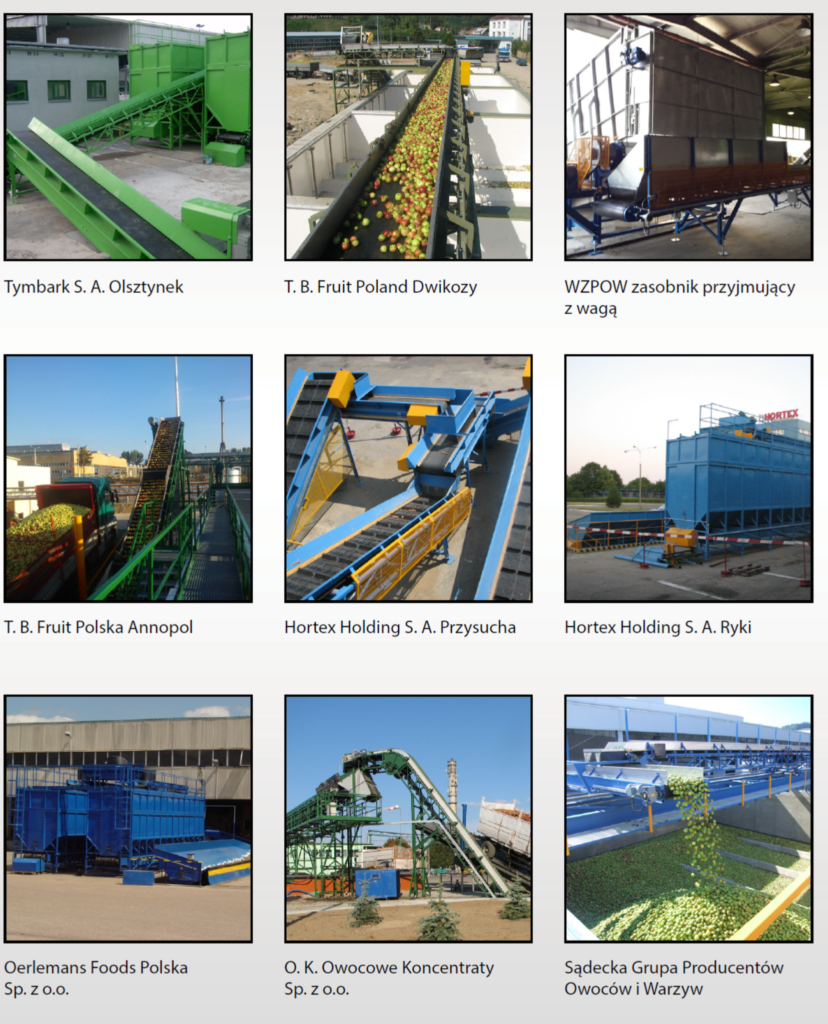

More offers

The scales-packer serves for an automatic batching – weighing according to the weight

of vegetables: potatoes, onions, beet etc. The device has two feeding belts 300 and 100

mm wide.

This sorter is designed for sorting potatoes and onions into four dimension fractions

within a scope of dimensions 25 x 25 mm – 90 x 90 mm (smallest adjustment of sieve

meshes 1 mm).

A brush cleaner OC 10 cleans root vegetables from dry dirt.

PTSP oblique-horizontal running belt conveyors feed raw material, i.e. potatoes, onions,

beet onto a sorter type M 612, ZS 140, ZS 180 or to other devices or transporters.

Hydraulic tippler for chest-palettes and containers quickly empties containers, chests

etc. filled with the product.

Drop shock absorber – Cascade serves for a cascaded transport (drop) during loading

into “BIG-BAG” sacks or containers.

Containers for fast receiving of root vegetables from self-tipping transport devices,

agricultural trailers or hydraulic container tipplers delivering onto further technological

devices.

Loading set for “BIG-BAGs” and

“DUO” containers.